Flow Analysis

When you need flow and thermal analysis, you need someone who really understands the entire process rather than people who just know how to run a simulation, at Mastip all our analysis is performed by experienced engineers.

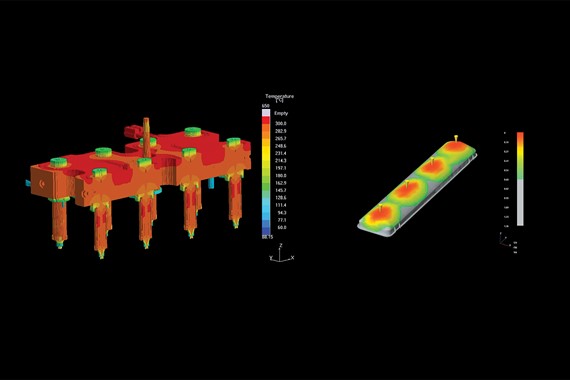

During the infant stages of a new mould build it is critical that your hot runner designer can provide input and feedback on the part design and layout of the mould. Analysis will assist with correct gate location and number of gates, warpage, shrinkage, pressure drop, weld lines, gas traps, shear stress, temperature rise and part fill time so the performance of the hot runner and the mould are optimised.

What differentiates our process from others is that we utilise the latest in material flow software analysis that exactly reproduce processing conditions. The heat-up stage, as well as the thermal evolution of the mold over multiple consecutive production cycles. This accurate calculation predicts the real temperature in each location of the mold during production, producing a condition that more closely reflects how the polymer sets inside the cavity. This allows us to accurately predict how long the polymer remains in a fluid condition so that post-pressure can be applied, or where the thermally induced deformation will most likely compromise part quality

Mastip can help provide either internal or independent levels of part fill analysis during the design process, assisting you to get the best performance from your manufacturing investment. Please contact us for more information